- सार्वभौमिक/तन्य परीक्षण मशीन

- हाइड्रोलिक

- गतिशील थकान परीक्षण प्रणाली

-

रोबोट स्वचालित परीक्षण प्रणाली

- प्रभाव परीक्षण मशीन

- संपीड़न परीक्षण

- मरोड़ परीक्षण मशीन

- झुकने परीक्षण

- रेंगना और टूटना परीक्षण मशीन

-

इलास्टोमेरिक असर परीक्षण मशीन

-

कप परीक्षण मशीन

- वसंत परीक्षण मशीन

- अन्य परीक्षण मशीन

- कठोरता परीक्षक

-

एनडीटी श्रृंखला

-

माइक्रोस्

- धातु विज्ञान

- परीक्षण मशीन सामान

- उच्च और कम तापमान कक्ष

-

इन्सुलेटर परीक्षण मशीन

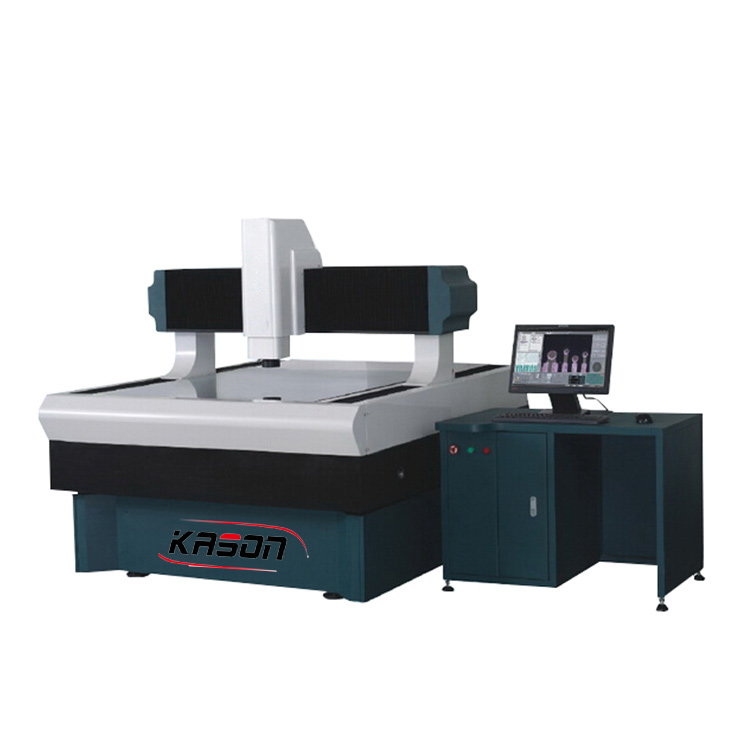

Bridge CNC Video Measuring Machine KS Series

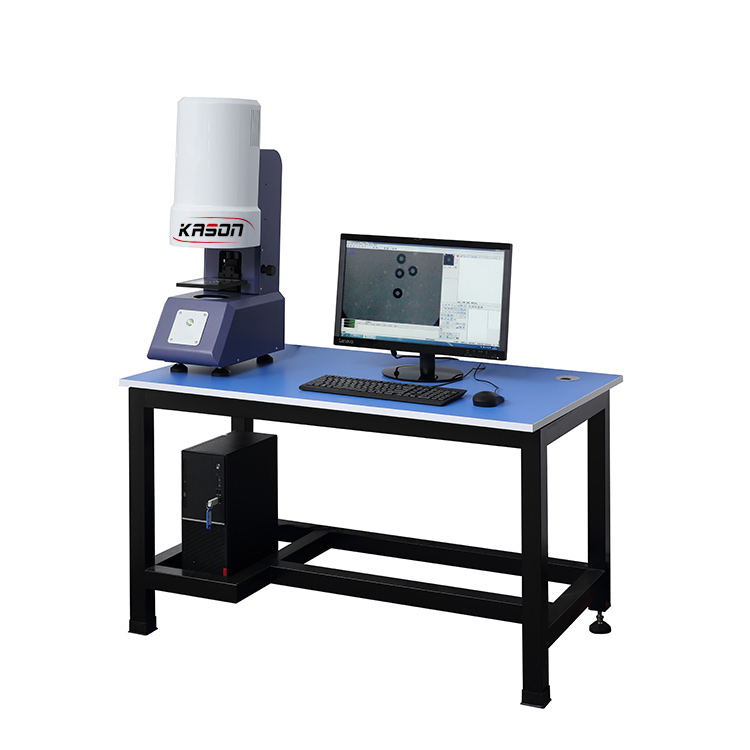

Product name:Bridge CNC Video Measuring Machine KS Series

Product categories:CNC Video Measuring System

Abstract:

KS series, bridge type CNC video measuring system developed by KASON

I. Usage

KS series is the bridge type CNC Video Measuring System developed by KASON. It adopts original Japan imported screw drive and servo control technology. Combined with auto measurement software developed by HST Group, it can achieve efficient and accurate measurement of large volume work piece, popular for precision parts inspection and quality control. It has been windely used in machinery, electronics, hardware, plastics, mould and etc.

II. Feature

1. It adopts TEO™ 1 / 2’’ color CCD camera and professional zoom lens, big FOV, guarantee clear image during fast moving image measurement.

2. Fixed bridge granite structure, with German & Japanese auto-control technology, can achieve high precision motion, high stability for measuring large volume work-piece.

3. Programmable control of integrated 8 regional independent light sources, achieve professional surface measurement. Swift batch measurement help to cut labor cost.

4. Coupled with U.S. 2D+3D optical metrology softwareRationalVue™, wonderfulmeasurement experience.

5. Option Renishaw™ touch probe & Keyence™ laser sensor available, high accuracy composite contact or non-contact 3D measurement available.

Model | KS-6040H | KS-6050H | KS-8060H |

Glass Size(mm) | 650*450 | 650*550 | 850*650 |

Stroke(mm) | 400*600*150 | 500*600*150 | 800*600*150 |

Machine Dimension(mm) | 950*1600*1580 | 950*1800*1580 | 1200*2000*1580 |

Weight(kg) | 1150 | 1350 | 1550 |

Scale Resolution | 1/0.5 μm | ||

Camera | TEO™ 1 / 2 "CCD Camera | ||

Zoom Lens | Manual Optical Zoom Lens, Magnification: 0.7-4.5X | ||

Video Magnification | 20-128X | ||

FOV | 11.1-1 .7 mm | ||

Accuracy E1* | Ex, y ≤ (3.0+L/200)μm | ||

Accuracy E2* | Exy ≤ (4.0+L/200)μm | ||

Illumination | Surface light and transmitted Light adopts white LED, brightness adjustable | ||

Power | 110V/220V AC 50/60Hz, Power consumption: 1000W | ||

*All data is tested according to Standard ISO 10360-7-2011

L is measured length (units: mm)

Specifications subject to change without notice.